Elastomers & Composites

Elastomers

-

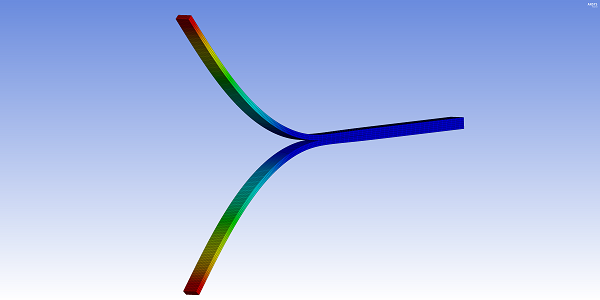

Proper analysis of rubber components requires special material modeling and nonlinear finite element analysis tools that are quite different than those used for metallic parts.

-

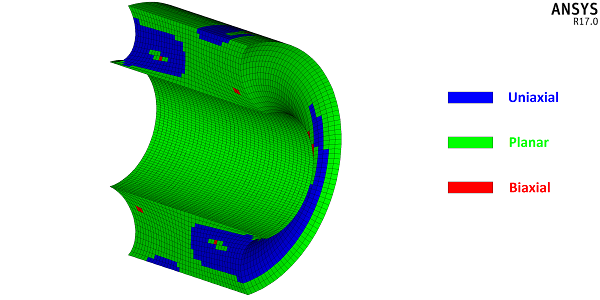

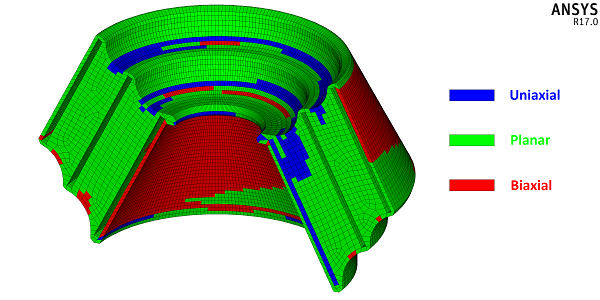

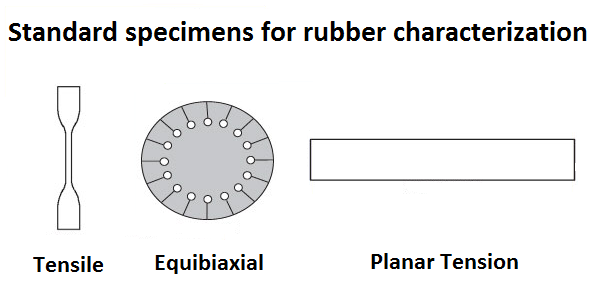

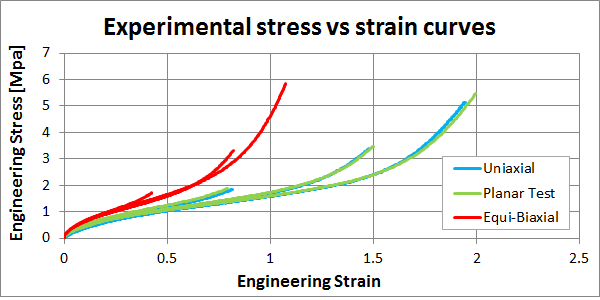

We have developed a procedure for the prediction of elastomers’ behavior based on experimental tests aimed to characterize the material in tension, compressione and shear. For incompressible materials like elastomers this is equivalent to perform tests in tension, equibiaxial tension and planar tension.

-

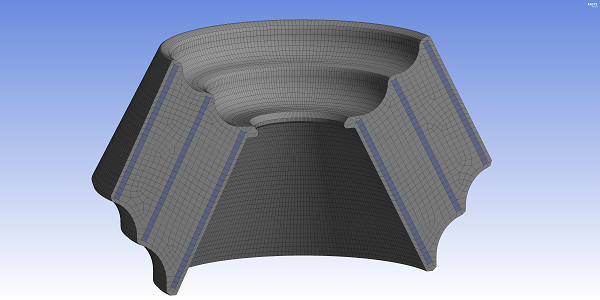

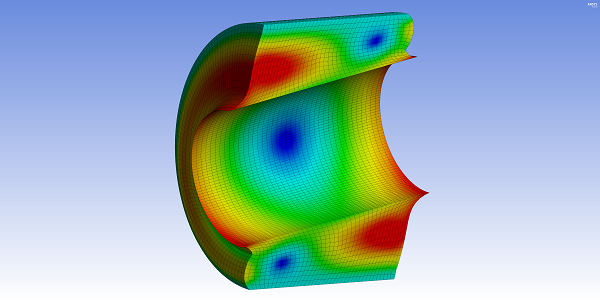

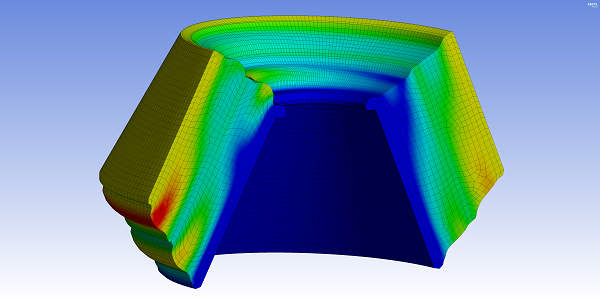

After a preliminary finite element analysis, performed with a reasonable material constitutive model, the finite elements of the numerical model are classified based on their dominant deformation mode. A further classification is performed based on the strain extension undergone by the elements in each of the three main states of stress. Based on such a classification, their constitutive material model is then appropriately modified and a final, more accurate finite element analysis is run.

|

|

|

|

Composites

-

The major advantages of composite materials include their ability to provide high performance, flexible shapes and low weight. However, when composites are used as an alternative to long-standing materials, such as metals, it is particularly challenging to determine their long-term reliability.

-

The most effective way forward, then, is to combine physical testing with robust simulation models. This allows manufacturers to reduce significantly the costs of prototyping.

-

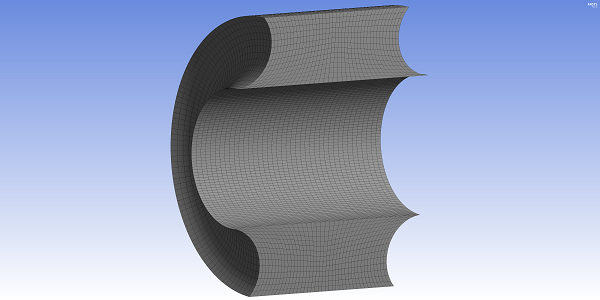

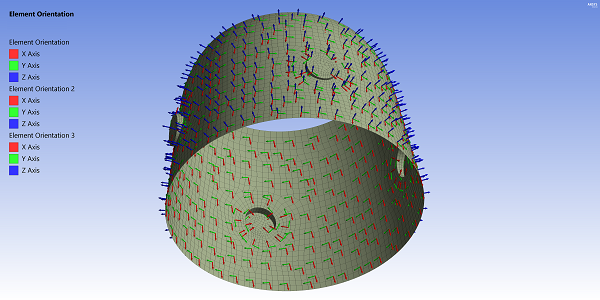

The challenge of simulating a composite material is to achieve an accurate depiction of its formulation. Unlike a conventional material, a composite is a mix of fibrous materials of different thicknesses that are layered to make a single material. The fiber orientation in each layer differs in terms of angles, thickness, and material from one layer to another. When performing a composite material simulation, it is necessary to accurately capture and define all of these components.

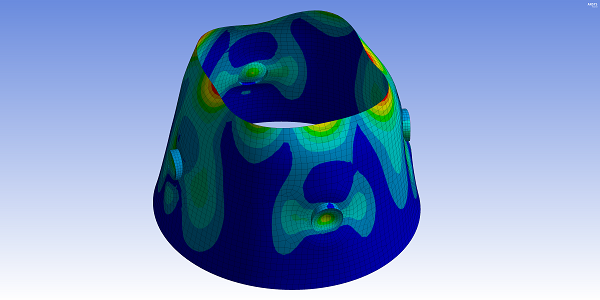

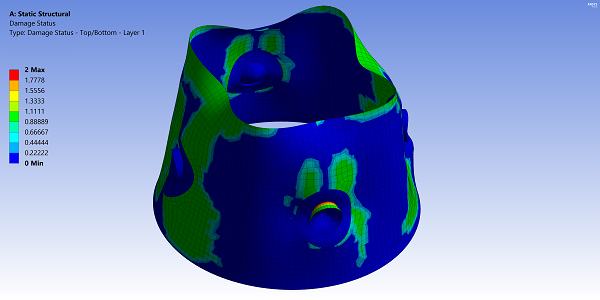

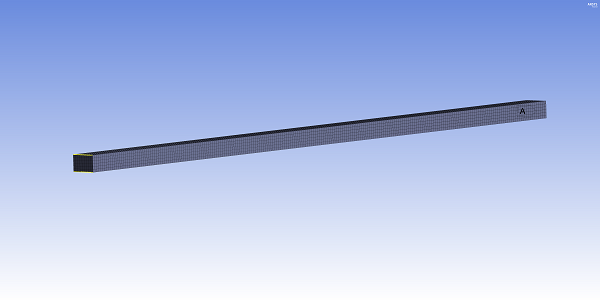

|

|